Rapier Looms

CRANK BEAT UP MECHANICAL:(FOR NORMAL FABRICS)

MODEL GA738-A (DOUBLE SHAFT-STEEL/CASTED WALL) MODEL SM787(GA738-A)

MODEL SM 787 GA738-A ( DOUBLE SHAFT – STEEL/ CASTED WALL):

- DOUBLE SHAFT LOOM

- FULL CRANK SHAFT

- AVAILABLE IN CASTED WALL AND ALSO IN STEEL WALL

- SPEED – 210RPM WITH 2HP POWER

- AVAILABLE IN TAPPET & JACQUARD MODEL ALSO

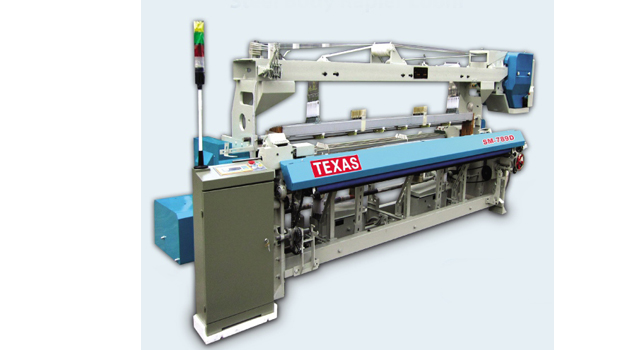

MODEL GA789D (DOUBLE SHAFT-HALF CRANK STEEL BODY WITH CENTRE DRIVE)

MODEL GA789D ( DOUBLE SHAFT – HALF CRANK STEEL BODY WITH CENTRE DRIVE ):

- DOUBLE SHAFT LOOM

- HALF CRANK SHAFT WITH BEARINGS

- AVAILABLE IN STEEL WALL

- BACK REST ALSO IN STEEL ADJUSTABLE

- BOTTOM CENTRE DRIVING SYSTEM

- SPEED – 250RPM WITH 2HP POWER

- AVAILABLE IN TAPPET & JACQUARD MODEL ALSO

MODEL GA736A (SINGLE SHAFT FOR HEAVY BEAT UP & HEAVY FABRICS)

Contact us more details…..

MODEL GA758M ( SINGLE SHAFT,HALF CRANK STEEL/CASTED WALL)

Contact us more details…..

MODEL GA738 (DOUBLE SHAFT CASTED / WALL-ECONOMIC MODEL)

Contact us more details…..

CRANK BEAT UP ELECTRONIC FOR (TERRY TOWEL FABRICS )

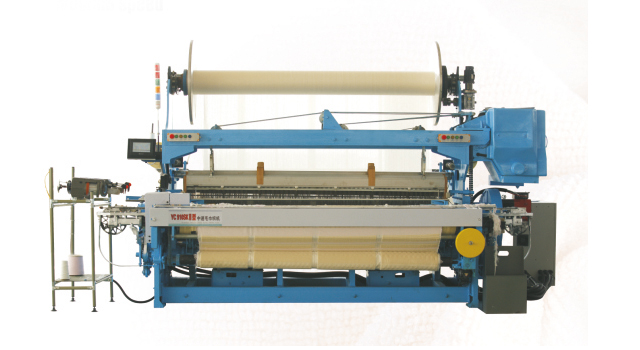

MODEL 910-SK-III ( FULLY SERVO WITH 5 SERVO DRIVE & ELECTRONIC SELECTOR & ELECTRONIC DOBBY) (YOUCHENG- BRAND)

MODEL 910-SK-III ( FULLY SERVO WITH 5 SERVO DRIVE & ELECTRONIC SELECTOR & ELECTRONIC DOBBY) (YOUCHENG- BRAND):

The Key To Invension –

- Version 2016 YOUCHENG touch screen full digit setting control system

- YOUCHENG new digit control piling mechanism (Patent No.:ZL 2013 10201793.9)

- Super servo power main motor system

- Broad width of aluminum reed 4 linkages beating up mechanism

- The longer filling picks mechanism

- The picks finding linkage mechanism without disengaging mechanism (patent No.:ZL 201410375947.0)

Specification Parameters –

- Width of loom(mm):2000、2300、2600、2800、3000

- Speed of loon: 180 to 250rpm.

- Control System: QUCHENG NEW 2016 VERSION with full digit control system, the whole working angle datum to be set directly , touch screen interface, digit control for taking up, let-off and let off terry yarn tension, digit control for piling terry, auto-picking finding, stopping at picks fixed, auto-pulling lace, the droppers for terry warp and ground warp to display separately, saving energy system, to calculate the statistics of shift output with production eficiency for 30 days.

- Mai motor: with super power motor system, without clutch and brake mechanism. Driving structure simply. maintenance more less.

- New type of framework, well- formed and stability.

- With digit control panel to set terry height and adjust terry height, such as wavy terry, saw-tooth of pros and cons terry, longituainal high & low terry, transverse high & low terry and 3-7 picks terry at random.

- To adopt the electronic servo control system for take up, each pick to be set to implement the synchronization weaving of changeable weft density.

- To adopt the electronic servo controlss stem is let off, weft density to increase and decrease synchronously.

- Digit control system reed motion with bearings structure of eccentric cam rotation for piling terry (Patent No. ZL 201310201793.9)

- To adopt servo motor for let off of terry warp, with digit control system for setting tension of terry and satin fabric, to

increase the tension for satin fabric automatically for weaving satin fabric demand. - Picking finding mechanism: original creative new mechanism without disengaging device for picking finding with maintenance free (patent: 201410375947.0)

- Fixed-picks stop function, to stop at any weft position at random, to stop the weft detecting device during weaving lace.

- The modified longer 6 linkages for filling picks, short 4 linkages beating for reducing selvedge yarn breaking.

- Box slay, large diameter rocking shaft with bearings and broad width reed structure to make sure the beating up fource for board, appearance is novelty.

- The large diameter burr fabric roller, to make sure without pulling terry length consistent. With new type of protection board. appearance is novelty.

- To set the piece of towel fabric, with automatic stop function when reaching the setting, with encoder meter length and the fixed length function.

- 20 to 24 levers electronic dobby with enclosed type and open type, can be worked with jacquard machine.

- 6 to 8 color selection function.

- Warp Beam : Terry beam,600mm, 700mm, 800mm Ground beam: 600mm、0700mm

- Maximum fabric diameter: 550mm, with YOUCHENG batching motion.

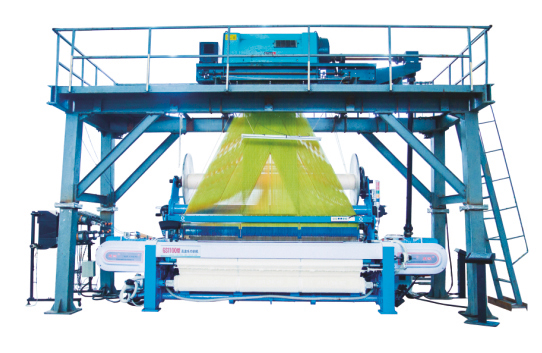

MODEL 920 SK-III ( FULLY SERVO WITH 5 SERVO DRIVE & BEAT UP WITH POSITIVE GEAR BOX - HIGH SPEED)

MODEL 920 SK-III ( FULLY SERVO WITH 5 SERVO DRIVE & BEAT UP WITH POSITIVE GEAR BOX – HIGH SPEED)

The key to innovation:

- Touch screen setting with full digit Control system of YOUCHENG 2016 version

- Superpower filling insertion for beating up mechanism, inflexibility relaying for weft yarn, more beating up force.

- The newest digit control system for piling mechanism (national patent: ZL2013.10201793.9)

- Super servo motor for driving main shaft

- The longer filling insertion mechanism

- Full digit control for pick finding mechanism national patent. ZL 2014103759470)

Specification parameter:

- Shedding: With bottom dobby or electronic jacquard: (cm):200,230,260,280,300,320,340.360

- Width of loom(cm) 200,230,260,280,300,320,340,360

- Speed of loom:225rpm to 280rpm

- Planet gear droven for beating up, inflexibility relaying weft yarn, rapier tape and rapier wheel contacting angle is 180 Planet gear droven for beatingun in degrees for high speed

- Box-type feed Siey, big rock shaft support foot and width of reed sley in order to make sure beatingup force without deformation at center of loom.

- Control system: To adopt YOUCHENG newest full digit control system 2016 version, to set all working angles on the panel directly, touch screen interface, digit control for take up and let off, digit control tension for terry beam, digit control for pilling terry, picks finding automatically, stop at fixed picks, pulling fringe automatically, the yarn broken of around beam and terry beam to display separately, energy saving system, 30 days production output and efficiency statistics.

- Main power system: Super power servo motor driving system without clutch and brake mechanism. Mechanism simplification and less maintenance.

- New box-type filling insertion mechanism, oil lubrication circulation automatically.

- With panel to set terry height by digit. and adjust terry height by touch screen, such as wavy terry, saw-tooth of pros and cons terry, longitudinal high and low transverse high & low terry with 3-7 picks terry at random.

- To adopt the electronic servo control system for let off of weft density to increase and decrease synchronously, performance sensitive and tension stability.

- Digit control system reed motion with bearings structure of eccentric cam rotation for piling terry (Patent No. ZL 201310201793.9)

- Adopt servo motor for let off , with digit control system for setting terry tension and satin fabric tension, to crease the tension for weaving satin fabric automatically in order to meet weaving satin fabric automatically in order to meet weaving satin fabric demand.

- Picking finding mechanism: original creative new mechanism without disengaging device for picking finding with maintenance free. (patent: 201410375947.0)

- Fixed – Picks stop function, to stop at any weft position at random, to stop the weft detecting device during puling fringe.

- The large diameter fabric roller, to make sure without pulling terry and terry length consistent. With new type of protection board, appearance is novelty.

- To set the piece of towel fabric, with automatic stop function when reaching the setting, with encoder meter length and the fixed length function

- 20 to 20 levers electronic dobby can be worked with jacquard machine.

- 6 to 8 color selection function

- Terry beam: 1000mm, 800mm Ground beam: 600mm、0700mm

- Maximum fabric rolling 550mm, YOUCHENG batching motion on request(constant tension control system

- Electronics dropper: 4 rows for terry warp, 2 rows for ground warp.

MODEL GA758M ( SINGLE SHAFT , HALF CRANK STEEL/ CASTED WALL) WITH 4 SERVO DRIVES

MODEL GA758M ( SINGLE SHAFT , HALF CRANK STEEL/ CASTED WALL) WITH 4 SERVO DRIVES

HIGH SPEED CAM BEAT UP ELECTRONIC ( FOR NORMAL/ TERRY TOWEL FABRICS )

MODEL GS1100 - ( SPEED - 500 RPM-190CMS)

MODEL GS1100 – ( SPEED – 500 RPM-190CMS)

Weaving specifications:

Weft density 5-120 picks/cm

Yarn count for Short fibre

500tex (1.2Ne) 5 tex(120Ne)

- The key to innovation:

- The digit control system with high speed reed motion piling terry Mechanism ( Patent No. ZL 2012 1 0559088.1) .

- Filling insertion at inching speed or high speed to handover the weft with accuracy and stability.

- The picks finding linkage mechanism without disengaging Mechanism ( Patent No. ZL 2014 1 0375947.0) .

- 16cm thickness wallboard for enforcing the stability

- To make sure the battening up for broad width of loom.with the oversize diameter oscillation shaft.

- New type YOUCHENG controls system with more humanization and more saving energy.

- Super power servo main motor

- YOUCHENG prompts:

” The mechanics of digit control piling terry has been got national patent of invention of China. It will cause you much trouble if you copy and/or buy imitation.”

Specification parameter:

- Width of loom: 220cm, 260cm, 280cm, 300cm, 320cm, 340cm, 360cm, 380mm.

- Speed of loom: 280rpm to 480

- Piling terry mechanism: The digit control system of high speed reed motion for piling mechanism No. ZL 201210559088.1).

- • Filling insertion mechanism: high speed parallelism rotation of upside down pinion rack mechanism for filling picks.

- Picking finding mechanism: original creative mechanism without disengaging device for picking finding with maintenance free. (patent: 201410375947.0

- Battening up mechanism: Conjugate cam drive with oversize.laneter shaft (100mm) for battening up.

- Guiding rail, rapier gripper, griper tape: the single suspension guiding hook, narrow tape, small gripper without hookup weft yarn to reduce the yarn broken, the yarn quality requirement is not high

- Main motor: Super servo power motor without clutch and brake mechanism.

- Weft selection mechanism: stepping motor drive with fan shape 8 colors selectors.

- Warp beam: Terry warp beam 1000mm, ground warp beam: 800mm

- Control system: YOUCHENG NEW 2016 VERSION with full digit control system the whole working any digit control for taking up, let-off and let off terry yarn separately, saving energy system, to calculate the datum to be set directly, touch screen interface, digit control for taking up, let-on tension, digit control for piling terry, auto-picking finding, stopping at picks fixed, auto-puling fringes, droppers for terry warp and ground warp to display separately, saving energy yo statistics of shift output with production efficiency for 30 days.

- Processing edit: with computer for editing, datum modification at touch screen, transforming document with U disk.

- Signal synchronization: to make communication and automatic circulation easier and simpler for editing and co-ordinate with jacquard.

- Wallboard: 16cm thickness of wallboard for enforcing the stability

MODEL -AJL900 ( HIGH SPEED AIR JET - TOWEL LOOM )

MODEL -AJL900 ( HIGH SPEED AIR JET – TOWEL LOOM )

The key to innovation –

- YOUCHENG newest structure of high speed reed motion pilling mechanism.

- Conjugate cam driven for beating up system to ensure the high speed insertion time with small shedding.

- 6 and 4 linkages combination of beating up system to ensure high speed filling insertion time.

- The optimal beating up for pilling balance mechanism.

- Bold size beating shaft to ensure the beating up force during high speed.

- Extra width loom with multistage beating up technology.

Specification parameter –

- Width of loom: 200cm, 230cm, 260cm, 280cm, 300cm, 320cm,340cm,360cm,380cm and 450cm

- Speed of loom: 380rpm to 700 rpm

- Piling mechanism: The newest digit control high speed reed motion for piling mechanism.

- Filling insertion mechanism: 2-4 spray nozzles/valves to save energy air jet filling insertion

- Picking finding mechanism: original mechanism without disengaging device for picking finding with maintenance free. (patent: 2014 10375947.0)

- Battening up mechanism: Conjugate cam drive with oversize diameter shaft ( 100 mm) for battening up.

- Weft selection mechanism: 4-6color weft selector.

- Warp beam: Terry warp beam 1200mm, ground warp beam: 800mm

- Control system: YOUCHENG NEW 2015 VERSION with full digit air jet control system, the whole working angle datum to be set directly, touch screen interface, digit control for taking up, let-off and let off terry yarn tension, digit control 10 P119 terry, auto-picking finding, stopping at picks fixed, auto-pulling lace, the droppers for terry warp and ground warp to display separately, saving energy system, to calculate the statistics of shift output with production efficiency for 30 days.

- Processing edit: with computer for editing, datum modification at touch screen, transferring document with U disk.

- Signal Synchronization: to make communication and automatic circulation with jacquard synchronously ( more easier and simpler for editing and co-ordinate with jacquard)

- Wallboard: 16 cm thickness of wallboard for enforcing the stability.

MODEL - HASMAX - ( SPEED- 600 RPM -190CMS ) FOR NORMAL FABRICS ONLY

MODEL – HASMAX – ( SPEED- 600 RPM -190CMS ) FOR NORMAL FABRICS ONLY